Over twenty years ago Pamela Richardson was having car problems and the family mechanic, Uncle Walter, was busy. When Pamela’s car broke down (again) across the street from a Mom and Pop garage, she must of thought it was fate… the guy checked under the hood and said he could fix the car by the next day—for $450. She was so proud of herself for taking care of her own business until her uncle told her she’d been ripped off. The mechanic had installed $20 thermostat, a repair that with her uncle’s help she could have done herself.

Uncle Walter told Pamela she better learn how to do things like this for herself or she would continue to get taken advantage of… advice that resonates with any Do-It-Yourselfer!

“That very week I went to the nearest skill center,” she said. Pamela enrolled in an automotive repair program where she learned that in order to be a master mechanic she’d have to know how to weld as well. A quick tour of the welding department and she was ready to sign up.

“The timing couldn’t have been more perfect because Maxine Waters, our State Representative, had poured money into the skill center to encourage females to enter into nontraditional crafts,” Pamela said.

“The timing couldn’t have been more perfect because Maxine Waters, our State Representative, had poured money into the skill center to encourage females to enter into nontraditional crafts,” Pamela said.

Game for something new, Pamela went home and rounded up four female friends and a sister and they all enrolled. A grant paid for training, books, weld gear, and even a stipend.

And talk about dedication: Pamela became pregnant three months into the program, but she continued until she became certified in December of ‘94.

What excites you about welding?

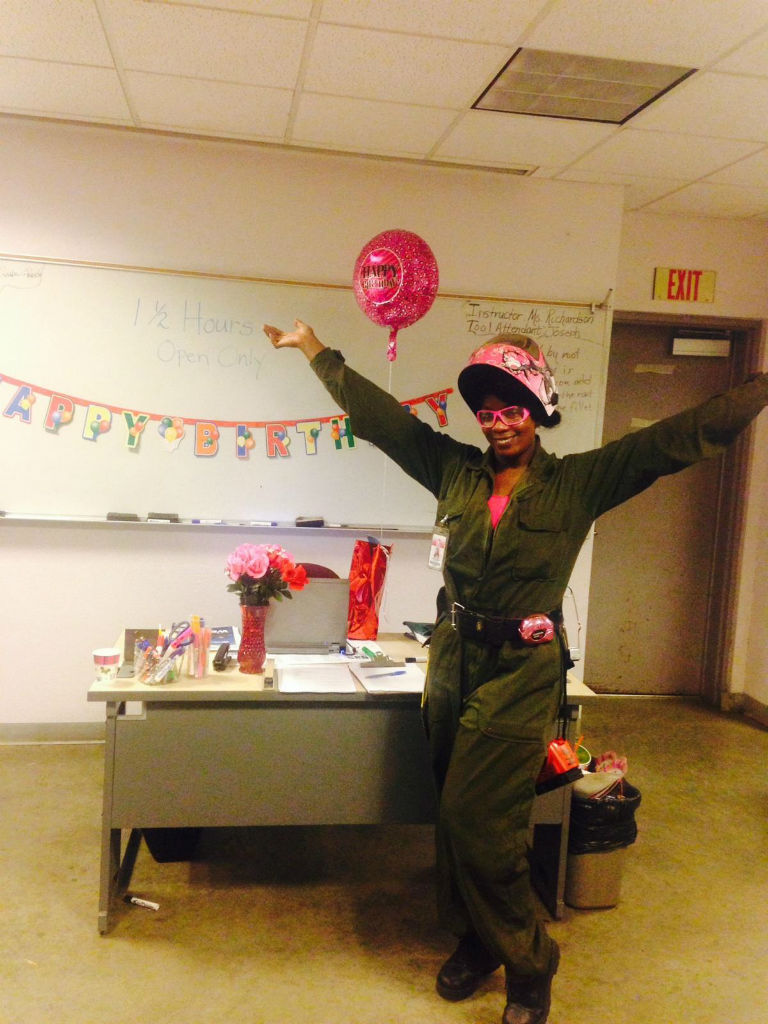

I am presently a Welding Professor at a community college full-time, and I love teaching people what I know. I love the way the guys get shocked when they see that I can explain AWS codes as well as weld various processes in various positions.

And what welding process(es) do you use most? … what process do you use the most or feel more familiar with?

I am an instructor, so I teach various processes, SMAW, GTAW, FCAW, OAW, OAC, GTAW, PAC, and pipe welding positions. I also train welders for the LA City Certification required on most construction jobs.

How did you train?

I went to adult school, Watts Skill Center and Abram Friedman Occupational as an expectant mother. I became certified 1 month before my son was born.

What kind of welding jobs have you held?

I was a welder for Local 108 Sheet metal JAC and worked on the Red Line of the Metro Rail. I presently weld for Tom Farrage, Inc. in my spare time when I’m not teaching. I was blessed to be able to work on the headquarters for well-known architect Thom Mayne who started the design firm Morphosis.

Have you experienced discrimination as a woman welder? if YES how have you handled it? if NO, why do you think that is?

I have been blessed that even when I knew I was being discriminated against, the Lord put me in a better position.

What advice would you give your 15-yearold self?

Hang in there, yours is coming!

What advice would you give young women interested in welding as a career?

Stick with it and don’t let the guys discourage you! Make sure you attain a degree so that you can expand your trade.

If you’re a woman interested in welding, be sure to check out Arc-Zone’s line of welding gear for women– welding apparel that fits women, welding gloves that fit (check out the AngelFire and Firefly gloves), and welding helmets that are fun.

And check out the other New Rosies we’ve featured, and tips for women in the welding industry.

Ask about our Welding Student Discount program.