April 2018: Swap torches w/ zero mess, notch pipes w/ ease, get polished, a talented Bulldog & kickin’ back welding

PRESTO-CHANGO W/ ZERO LOSS

Got >1 TIG torch? Now you can swap-out torches in a Snap. No Tools Required! Never deal w/ excess water, gas or money draining out of TIG lines again. With our Zero Loss Quick-Release System, just snap in the torch you need & you’re good to go. We offer conversion kits for as many torches as you have, so you can literally plug-n-weld all day… We’ve even got torch packages, so get all the #toolsthatmakeyoumoney from Arc-Zone. We’re here to keep that green stuff flowin your way.

ANOTHER NOTCH IN YOUR TUBE

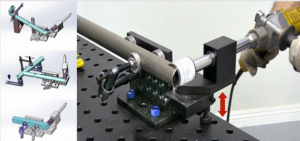

If you weld pipe, you’ll love the new Modular Tube & Pipe Notcher (SHT-ATN100). Complete your 1st notch with a drill press, then use the BuildPro® Notcher to align angles & control the length of the 2nd notch accurately & easily. Position the two soft-facing V-Blocks and clamp as needed.

- Notch 1″- 2¹/²” OD pipes or square tubes at any angle

- Cutter centerline is height adjustable

- Adjust cutting angle up to 90º

- Works with 1/2″ Drill

- Accepts hole saw thread sizes: 1/2″-20, 5/8″-18

- 25 mm Steel Shaft

- Double Bearing Block

The popular Multitool 2×36 belt grinding attachment is available mated to a 1 hp grinder. More than a traditional belt sander, this versatile tool has a belt speed of approximately 5,400 surface feet per minute which allows for material removal up to 5 times faster, along with 5 grinding areas in one machine. The unit also offers platen grinding, slack-belt grinding, disc grinding, and stone wheel grinding!

FROM TIG WELDER TO ENTREPRENEUR

“WORK” SMARTER

The folks @world_of_engineering re-posted this video from@ryancj55… and we couldn’t help but share it with y’all. The only thing missing are tunes & some of Ryan’s famous BBQ to help pass the afternoon as he seals up that pipe. Here’s to deploying tools that save you time, let you take a load off, and help you build it bigger & better. Spring flowers & the smell of smoked meats are in the air… Enjoy!

#WELDLIKEAPRO

In 1996, Aaron Biefer (@bulldog_welding) started as a CAD designer in the automotive industry, and later moved to welding engineer. He began welding ~20 years ago to keep his old car on the road. From the very 1st arc with that ol’ Lincoln buzz box, he was hooked. Fast forward to today, he & Kelsey (his Rock ⭐) are engaged and live in an old farm house with Owen & Ben, their two English Bulldogs. The Bulldog Welding “world headquarters” is located in a barn on the property. Aaron, like most of us, has learned a ton from his mistakes as well as from Jody’s Tips and Tricks videos. He attributes his artistic flare for metal sculpture to his mom, an art teacher. Aaron now tackles everything from architectural to heavy equipment repair, and says that he’s driven to become better with every project. We salute Aaron and welders everywhere who pursue their passion each day that they strike that arc.