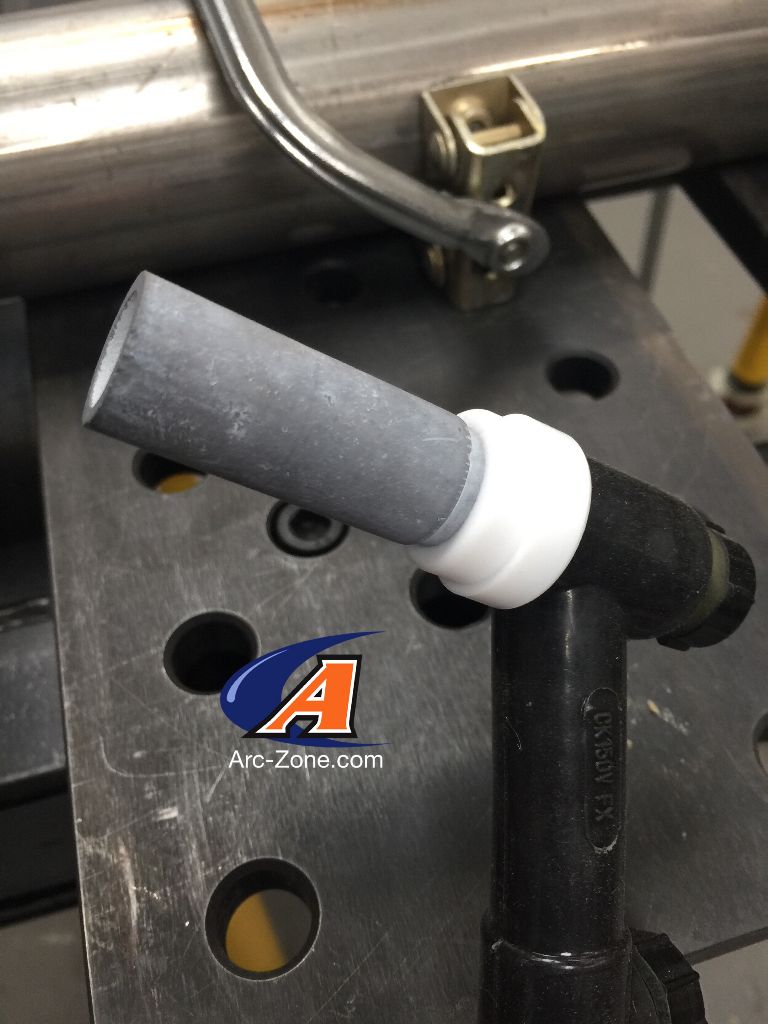

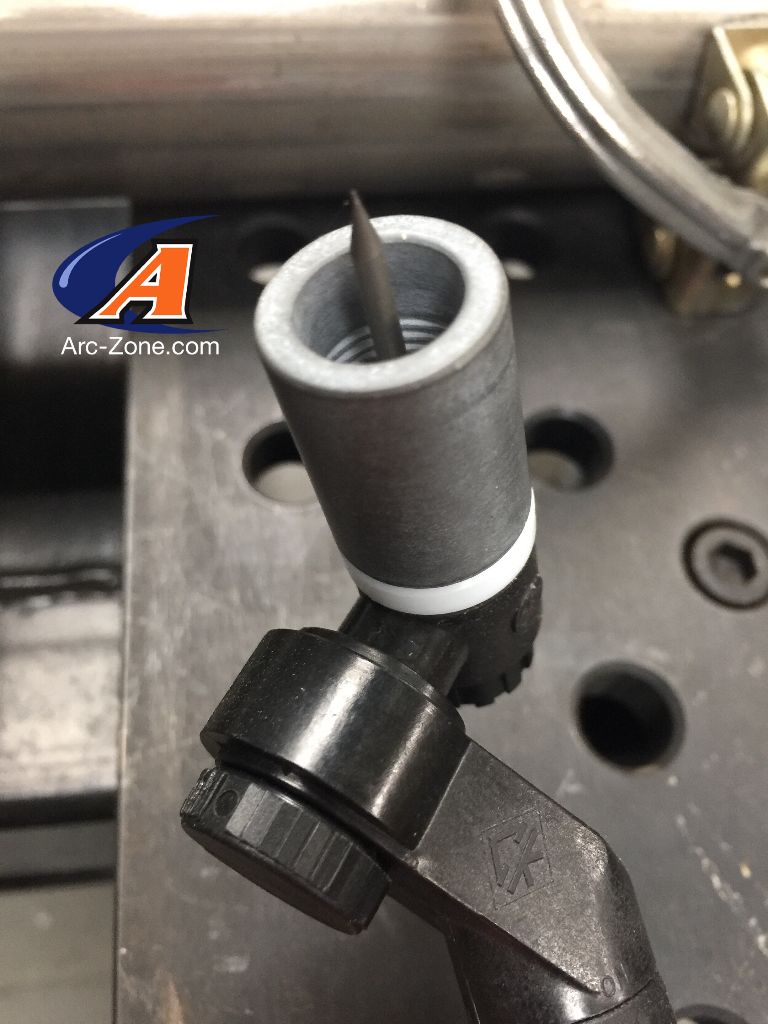

SuperCups are best for high amperage AC TIG welding aluminum jobs were a balled tungsten & high amperage can spell disaster for Pink Alumina cups. Super Cups are made for high amp, high reflective heat jobs!

Super Cups can take ultra-high temperatures & virtually eliminate thermal shock (when your pink gas nozzle tip blows off, cracks, splits & melts) when exposed to high AC amperage TIG welding. Now you can run your tungsten flush with the cup orifice & put the power down for those yacht towers, railings, & production aluminum TIG jobs!

High performance Super Cups reduce thermal conductivity (heat transfer) by nearly 40%, when compared to standard Pink Alumina cups. Made from modern advanced materials, these Silicon-Nitride gray cups are oven cured in a pure nitrogen environment to promote a much denser grain structure, for long trouble free performance💥

⚡Arc-Zone Pro Tip:⚡

When welding aluminum you can benefit from using a smaller I.D. cup size like a #4= 1/4″, or #5 = 5/16″. Smaller cup orifice size improves the AC cleaning cycle of your welding machine & helps to focus the arc energy toward the weld joint. Need even more heat / power? Try a mix of 75% Argon 25% Helium to improve shield gas ionization & gain as much as 25% more arc energy which makes for a hotter arc column at a given amperage setting. SuperCups are Available now in our webstore Arc-Zone.com