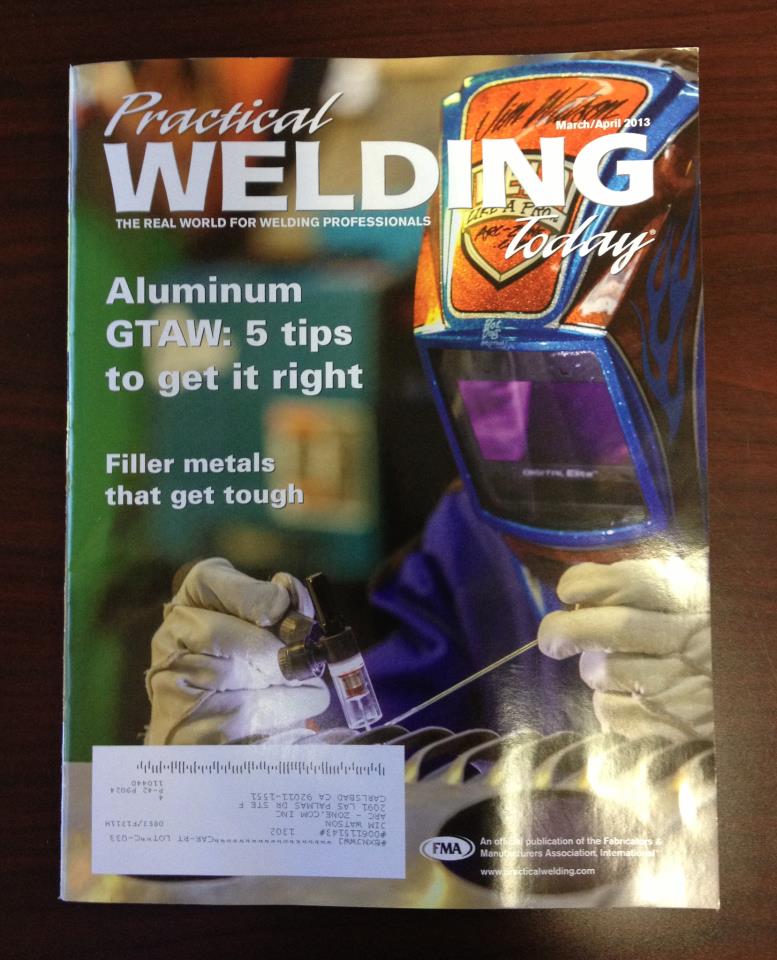

Back in March Arc-Zone contributed an article to The Fabricator magazine on TIG welding aluminum– and a photo for the cover that featured Jim Watson throwing down a TIG weld with his amazing helmet customized by the incomparable custom painter Pete “Hot Dog” Finlan. We got so excited to share the news of the helmet, I don’t think we ever really talked much about the article, “5 tips for successful aluminum GTAW”!

Back in March Arc-Zone contributed an article to The Fabricator magazine on TIG welding aluminum– and a photo for the cover that featured Jim Watson throwing down a TIG weld with his amazing helmet customized by the incomparable custom painter Pete “Hot Dog” Finlan. We got so excited to share the news of the helmet, I don’t think we ever really talked much about the article, “5 tips for successful aluminum GTAW”!

Aluminum is a pretty amazing metal. It’s lightweight yet strong making it perfect for industries like transportation, aerospace, automotive, power transmission, and construction. It’s also corrosion-resistant and is easily machined. And it looks good.

Aluminum unfairly gets a bad rep for being difficult, but TIG welding aluminum doesn’t have to be. It’s all about understanding the metal and taking the necessary steps to create a successful weld.

Our 5 Tips for Welding Aluminum include:

1.Remove the Oxide Layer. This involves taking some extra steps before you start to weld like chemically or mechanically removing that oxide layer.

2.Choose the Right Shielding Gas. Your best bet is going to be a 75/25 mix argon and helium.

3.Learn the Truth About Tungsten. Don’t go green (AWS classification EWP, color code green). Heck, don’t even go red (EWTh-2, color code red) unless your welding application specs it out (in which case Arc-Zone has plenty of high-quality tungsten electrode options for you). Your best bet these days is rare-earth tungsten (EWG, color code sky blue). We recommend ArcTime™ Brand Hybrid Tungsten. Not only is it an excellent choice for welding aluminum, it’s great on other metals as well and it’s non radioactive.

3.Learn the Truth About Tungsten. Don’t go green (AWS classification EWP, color code green). Heck, don’t even go red (EWTh-2, color code red) unless your welding application specs it out (in which case Arc-Zone has plenty of high-quality tungsten electrode options for you). Your best bet these days is rare-earth tungsten (EWG, color code sky blue). We recommend ArcTime™ Brand Hybrid Tungsten. Not only is it an excellent choice for welding aluminum, it’s great on other metals as well and it’s non radioactive.

4.Select AC. DC doesn’t offer the cleaning properties necessary to break through that oxide layer on your aluminum.

![]() 5. Invest in a High-quality Torch. One of the reasons we recommend only the best TIG welding torches from CK Worldwide and Weldcraft is that with a quality manufacturer you get better performance. This is especially true when TIG welding aluminum where you need a TIG torch engineered to handle the heat and manufactured with quality materials that also handle heat better and last longer. Check out the article we wrote a while back, “TIG Torch Materials–What’s the Difference” if you want to know more.

5. Invest in a High-quality Torch. One of the reasons we recommend only the best TIG welding torches from CK Worldwide and Weldcraft is that with a quality manufacturer you get better performance. This is especially true when TIG welding aluminum where you need a TIG torch engineered to handle the heat and manufactured with quality materials that also handle heat better and last longer. Check out the article we wrote a while back, “TIG Torch Materials–What’s the Difference” if you want to know more.

There are a lot of great details over on the The Fabricator magazine website where you can read the whole article, “5 tips for successful aluminum GTAW”.